Skilling And Upskilling Programme

Specific Training in any of the department/ shop of industrial manufacturing unit like Design, QA (Quality Assurance), Press Working/ Fabrication, Welding, Machining/ CNC Machining, Plastic Moulding, Tool Room, Maintenance, Store & Dispatch, HR Practices) as per National Occupational Standards (NOS) for Individuals.

Internship Training Programme (ITP)

Basic Level Industrial manufacturing knowledge with theoretical Class room Session and On Job Real Time Training for Diploma/ B.Tech students of Polytechnic/ Engineering Colleges/ Technical Universities in any industrial manufacturing process and department like Design, QA, Production, Tool Room, Maintenance, Purchase,Marketing, HR Practices under our society’s knowledge driven programme “CoPTE” (Centre of Professional Training Excellence) for Individuals or group

Duration- 1 month to 6 months

Qualification Requirement- Under Graduate/ Graduate Course Students

Professional Training Programme (PTP)

Specific Training in any of the department/ shop of industrial manufacturing unit like Design, QA (Quality Assurance), Press Working/ Fabrication, Welding, Machining/ CNC Machining, Plastic Moulding, Tool Room, Maintenance, Store & Dispatch, HR Practices) as per National Occupational Standards (NOS) for Individuals.

Duration- 3 months to 6 months

Qualification Requirement- School Drop Outs, ITI’s, Diploma Holders, Under Graduate/ Graduate Course Students, Working/ Experienced Industrial Employees

Specialized Training Programme (SPTP)

Specialized Training in specific areas of manufacturing process Design Simulations, HR Practices, Programme Management, Costing, Purchase & supply chain, Store & Inventory Management, QA Standard Room Practices on specific request of the Industries, Associations or Individuals

Duration- 15 Days to One Month

Qualification Requirement- ITI’s, Diploma Holder, Engineering Graduate, Working/ Experienced Industrial Employees

Synchronized Training Programme (SYTP)

A very specific type of training programme for working skills enhancement intended for manufacturing industries at their site for their employees or industry sponsored candidates as per their TNI (Training Need Identifications) requirements. This programme is based on techniques of TPS (Toyota Production Systems), lean Manufacturing, TPM (Total Productive Maintenance).

Duration- As per Training Content or Industrial specific requirement

AutoCAD/Engineering Drawing with CAD

Maintenance Assistant

Process Validation Executive

Process Tryout Engineer

Method Study Executive

Manager Manufacturing Quality

QA Standards In- Charge

Manager Customer Quality

Manager Supplier Quality

Assembly Line Supervisor

Vehicle Assembly Fitter Level 4

Machine Shop Setter

Painting Supervisor

Automotive Paint Shop Assistant

PDC Casting Operator Level 4

Customer Relationship Executive

Maintenance Technician Mechanical Level 3

Maintenance Technician Electrical Level 3

Maintenance Technician Mechanical Level 4

Maintenance Technician Electrical Level 4

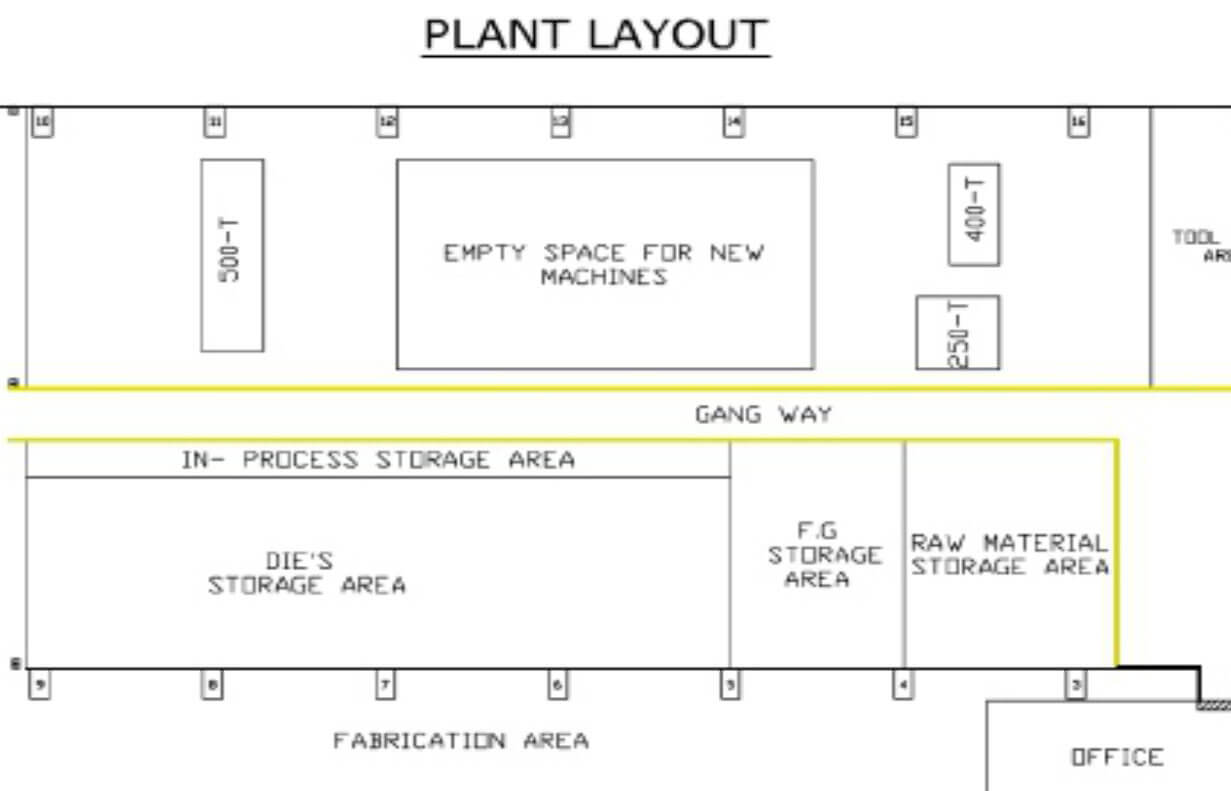

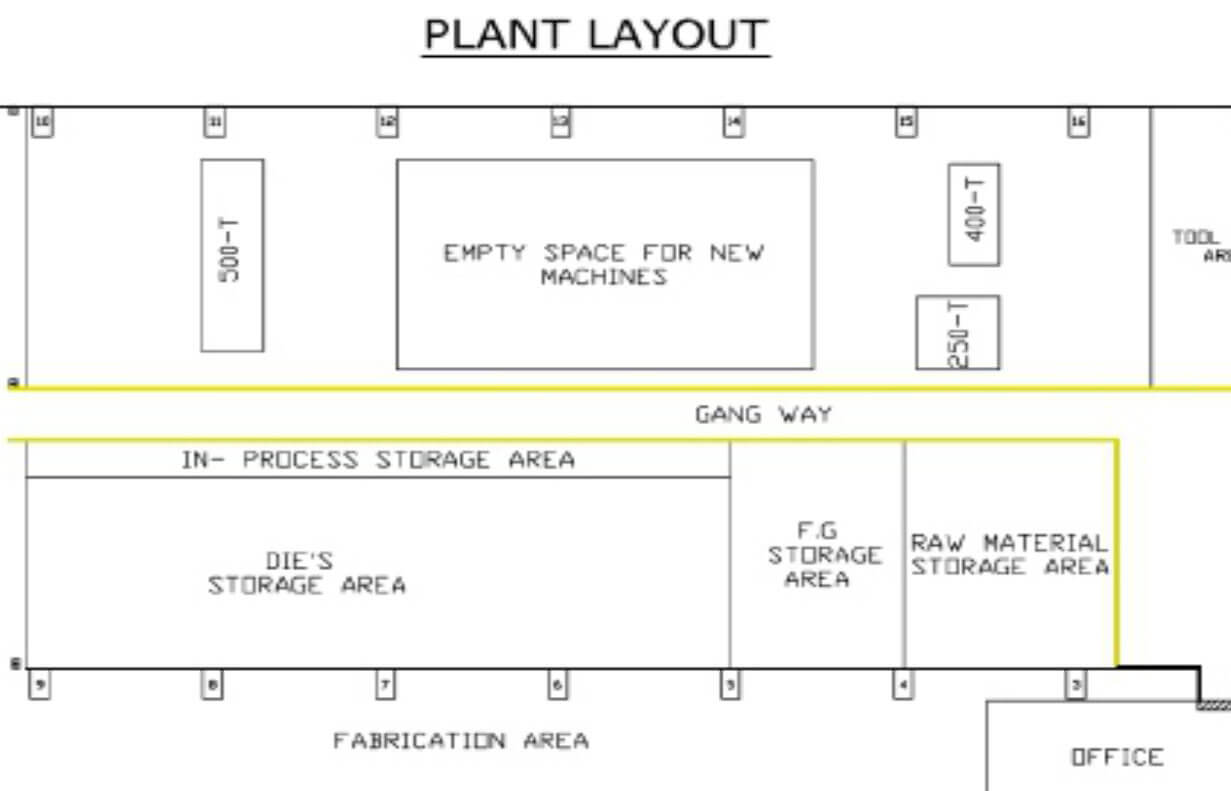

Industrial Engineer (Layout Design)

Industrial Engineer (Workstation Design)

Vendor Development Executive

Material Coordination Manager

Parts Picker

Packing Executive/Packing Assistant/Packer

Loading and Unloading Operator/Loader

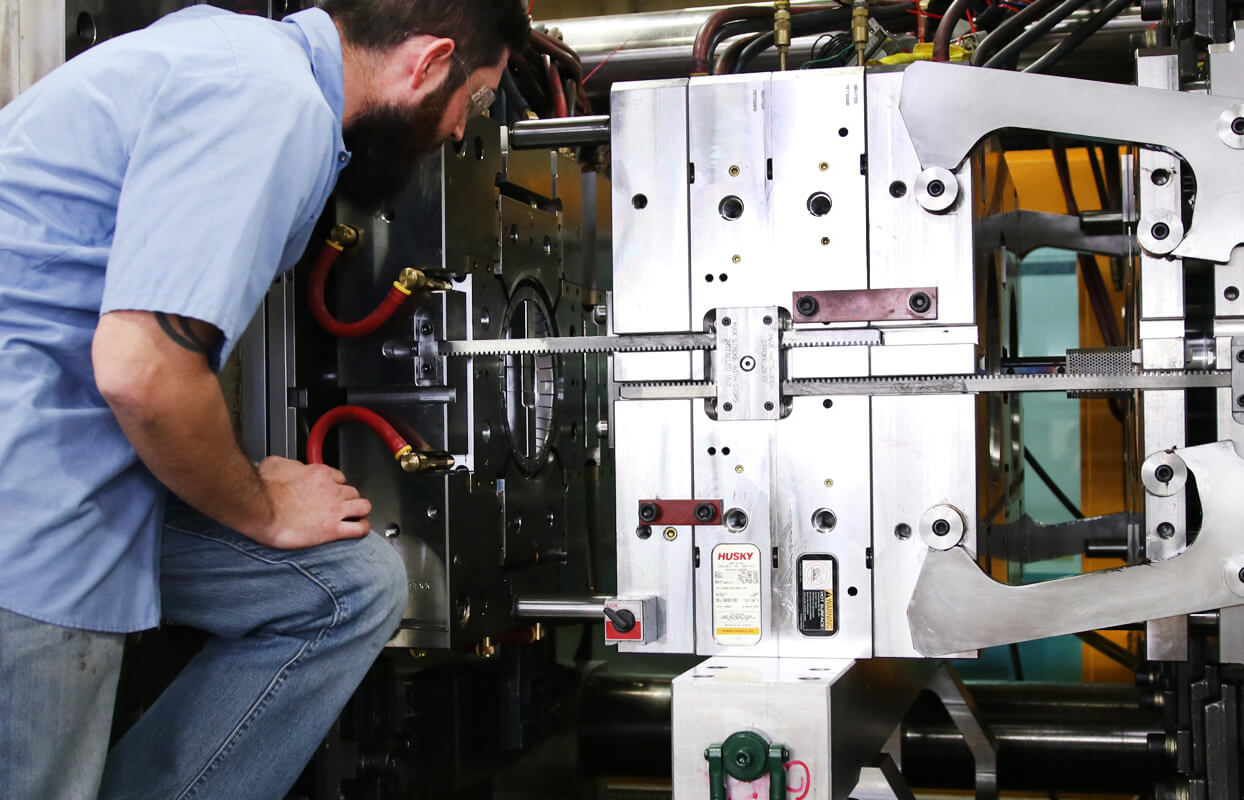

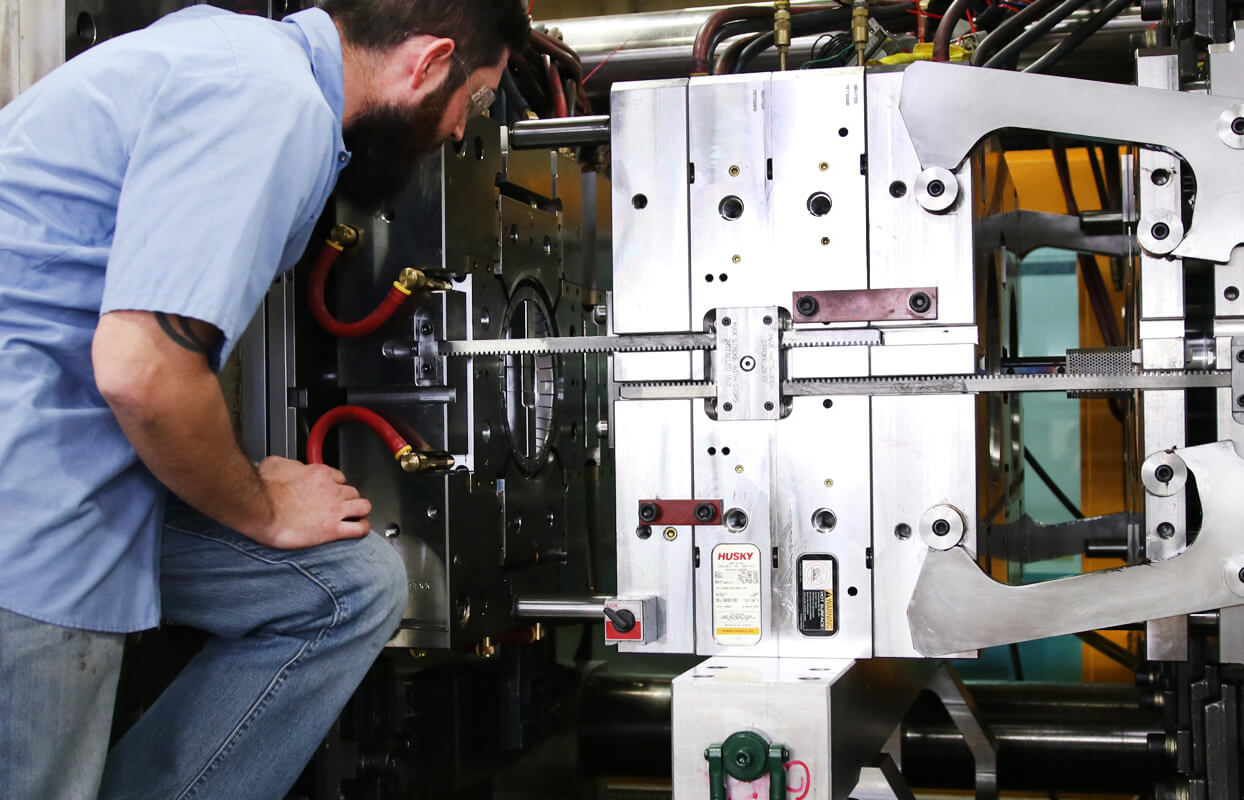

Plastic Moulding Shift-In-Charge

Plastic Moulding Supervisor

Plastic Moulding Helper

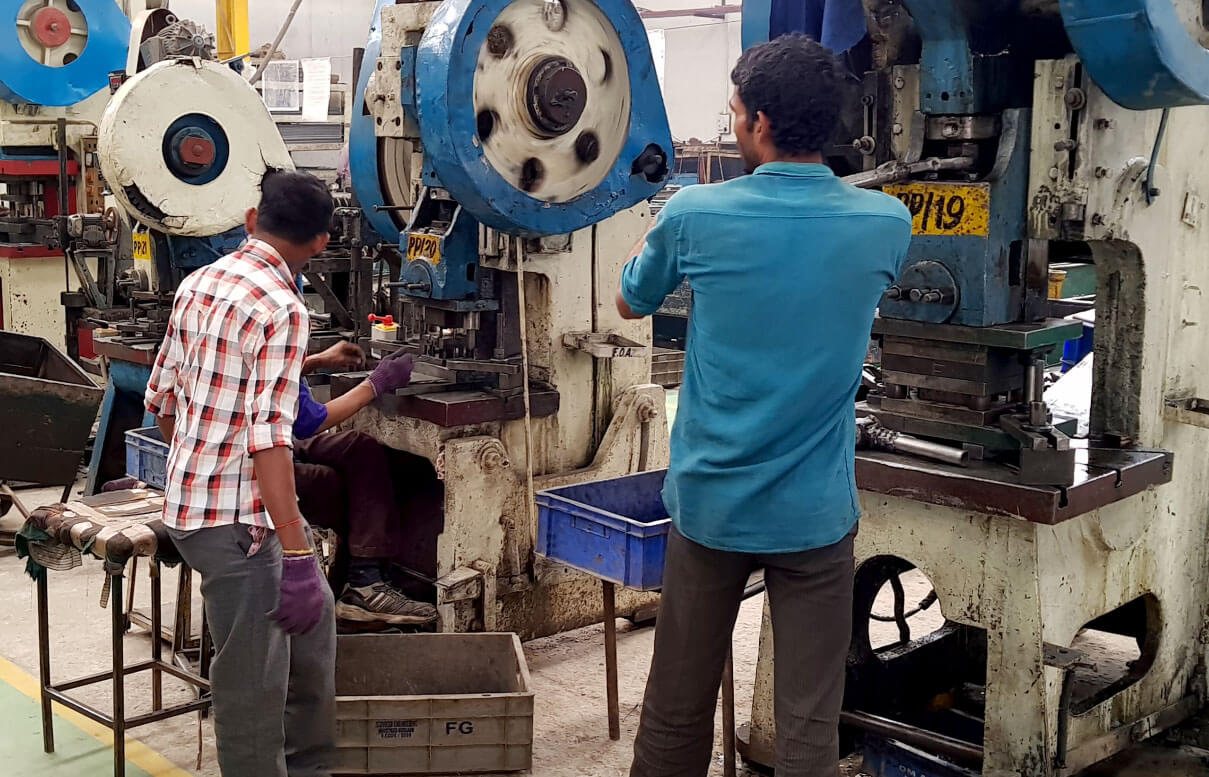

Press Shop Supervisor

Press Shop Operator

Press Shop Helper

Press Shop Line – In charge

Soldering and Brazing Technician

Welding Machine Setter/Master Welder

Welding Supervisor

Welding Technician L4

Welding Technician L3

Welding Assistant

Machine Shop Setter

Machine Shop Supervisor

CNC Operator Machining Technician Level 4

Machining Assistant

CNC Operator Machining Technician Level 3

Plastic Moulding Shift-In-Charge

Plastic Moulding Supervisor

Plastic Moulding Helper

Plastic Moulding Operator/Technician

AutoCAD/Engineering Drawing with CAD

Draughtsman/Draughts person

Executive, Proto Manufacturing

Prototyping Engineer

Equipment Designer

Tool Room Supervisor

Tool Room Operator/Technician

Tool Designer

Manager Manufacturing Quality

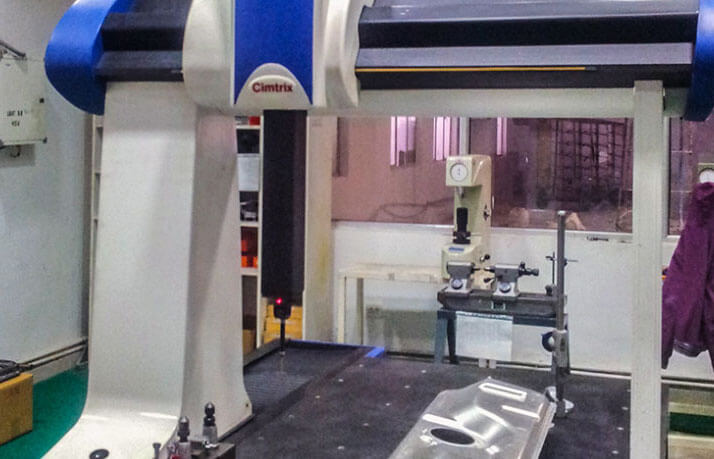

QA Standards In- Charge

Manager Customer Quality

Manager Supplier Quality

QC Inspector Level 4

QC Inspector Level 3

Maintenance Assistant

Maintenance Technician Mechanical Level 3

Maintenance Technician Electrical Level 3

Maintenance Technician Mechanical Level 4

Maintenance Technician Electrical Level 4

Process Validation Executive

Process Tryout Engineer

Process Design Engineer

Method Study Executive

Industrial Engineer (Layout Design)

Industrial Engineer (Workstation Design)

Painting Supervisor

Vendor Development Executive

Material Coordination Manager

Parts Picker

Packing Executive/Packing Assistant/Packer

Loading and Unloading Operator/Loader

PDC Casting Operator Level 4

Assembly Line Supervisor

Vehicle Assembly Fitter Level 4